UNLV engineering students have multiple motives in design contest

On most class projects, students are concerned with their grade. At the Fred and Harriet Cox Senior Design Competition, engineering students at UNLV also are concerned with winning cash and maybe even getting their project on the market.

“The senior design project is a requirement of all graduating seniors (in engineering) throughout the world,” said Rama Venkat, dean of the Howard R. Hughes College of Engineering. “We started it as a competition, giving out prize money and medallions for different categories, and that got a lot of interest.”

Seniors work in teams to plan, design and create prototypes of a product as part of the competition, which began in 2001 and is held in the school’s engineering department. Many draw from real-life challenges. The school seeks project ideas from medical professionals, manufacturers and others.

“It’s primarily an academic exercise, but over the years several of the projects have received U.S. patents,” Venkat said. “At least one is being worked on at a company in Henderson, and several are attempting to become startups.”

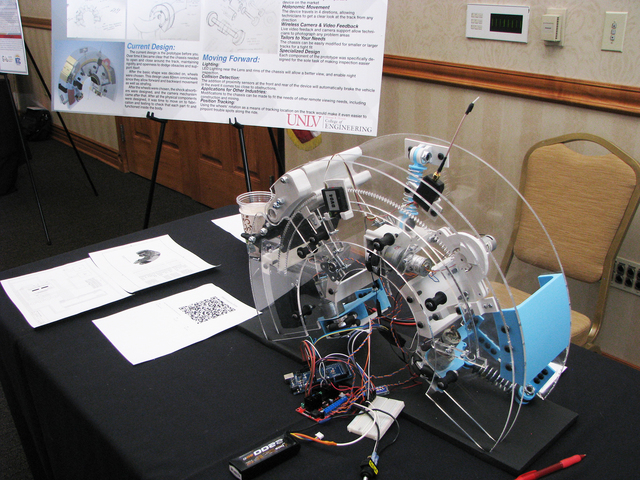

Projects are presented each semester. Twenty-five were presented this time around, including an efficient UNLV parking solution, a 3-D room scanner, a weld-inspection robot for roller coasters, a system for removing the chemical element Selenium from the Las Vegas Wash and a super splint.

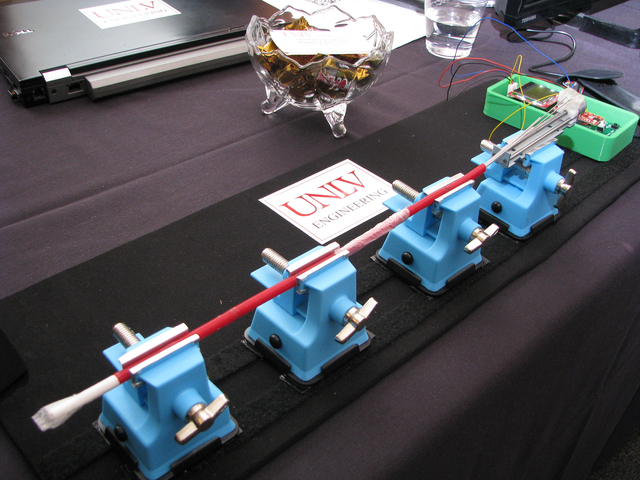

Two projects tackled different aspects of similar technology. The automated hot pinning machine project designed by Cory Nichols and Rebecca Seddon dealt with automating painstaking work to refine small glass tubes used in precision syringes.

“The initial cut is done with a diamond saw, and that creates rough edges that would damage the syringe,” Nichols said. “Hot pinning smooths the edges by heating the glass while it is on a lathe. The work is done by hand, and it’s laborious.”

The challenge in creating the smooth beveling is that heating the tube shrinks it, so it’s necessary to widen the tube by spinning it while it is heated. The designers say the automated process would save time and take some guesswork out of the process.

Another team worked on another intravenous challenge: providing anesthesia for varicose vein treatment in a less painful and more efficient manner.

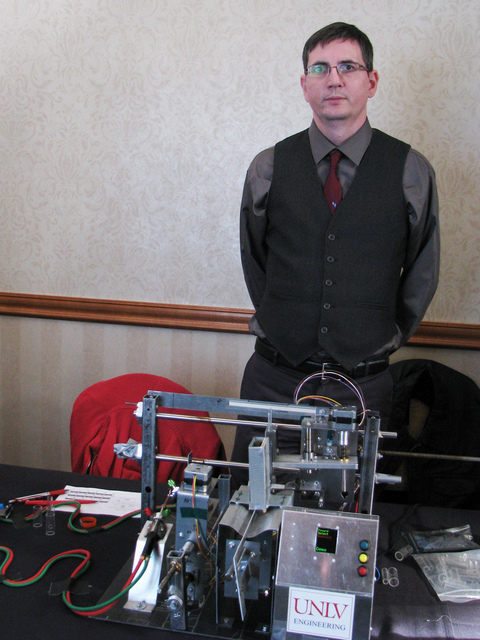

Donaji Jimenez, Raymond Lopez, Ralph Mago and Dominic Picardal worked on Project V, a rapid intravenous anesthesia delivery system. One of the treatments used is “radiofrequency ablation,” a procedure that destroys the offending veins via heat provided by ultrasound administered through a radio frequency catheter. Currently anesthesia is provided via seven to 10 injections along the vein through the skin and muscle.

“That’s the longest single part of the procedure; it takes up over half the time,” Mago said. “Our device would result in less pain for the patient and cut down on the delivery time.”

Project V is an anesthesia catheter that uses the same path as the radio frequency catheter and requires no extra injections through the skin. The device would be inserted all the way in and twin needles would then come out of the head of the device at an angle, piercing the vein wall to administer the anesthesia. It would then be pulled out a bit and the procedure would repeat. The same number of injections would be required, but without repeatedly going through the patient’s skin and muscle.

“We started with a giant prototype made of PVC pipe that was 10 times the scale to show the concept,” Mago said. “We gradually shrunk down our prototypes to one that is only twice the size that is needed for the final device. We got a comment from one of our mechanical engineering professors that it would work on an elephant.”

The project would need to be scaled down to 2.5 millimeters to be brought to market.

The competition’s $40,000 to $45,000 in cash prizes are funded through an endowment by the Fred and Harriet Cox Foundation and several industry sponsors. There is a grand prize, and prizes are awarded in separate disciplines and for commercial viability and potential. There is also a people’s choice award. The organizers say the prizes foster creativity and drive students to create useful and functional solutions.

To reach East Valley View reporter F. Andrew Taylor, email ataylor@viewnews.com or call 702-380-4532.

ABOUT THE COXES

To learn more about Fred and Harriet Cox, click here.