Behind the scenes of a Las Vegas marijuana testing lab

The space is no bigger than a good-sized office break room. On beige counters along the walls and on an island in the center sit off-white rectangular boxes that could be copiers or printers.

But the several hundred thousand dollars of highly sensitive scientific equipment in this room — and others like it — will be key to ensuring medical marijuana sold in Nevada is safe.

A private, state-licensed laboratory like DigiPath must test each batch of marijuana before it is sold to the public — or sold to producers who make edible products. The labs also will have to test each batch of marijuana-infused “edibles,” such as lollipops or cookies, before they are sold.

The state approved 17 labs in Nevada, 15 in Clark County and two in Sparks.

CEO Todd Denkin said DigiPath has put $1.4 million into its lab in an anonymous industrial park just west of Interstate 15, not far from McCarran International Airport.

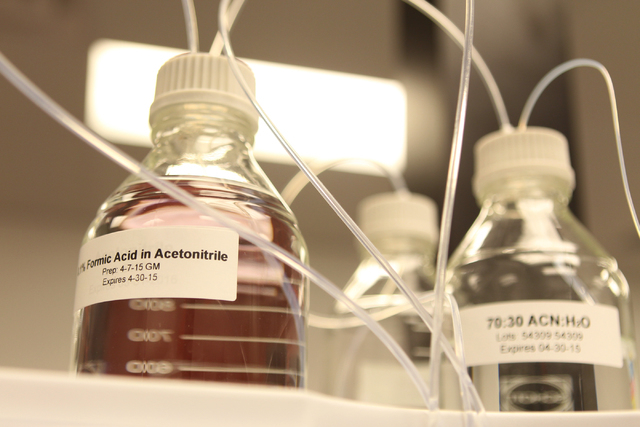

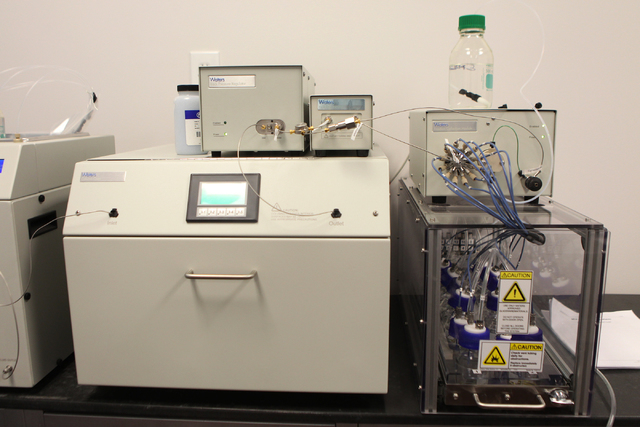

One machine alone, a mass spectrometer that uses liquid chromatography to measure pesticide residue, cost $250,000. The ordinary-looking white walls are antimicrobial, as is the ceiling. There also are isolated airflow systems in some areas.

Like growers and dispensaries, labs have spent millions getting ready and endured months of delays as a state advisory committee went through several false starts in figuring out the rules for pesticides.

But the committee finally made a recommendation Thursday. And with state lawyers ruling that no pesticides can be used — at least until a poorly written regulation can be changed later this year — the testing guidelines appeared to be nearly in place.

DigiPath’s official state inspection is scheduled for Monday, and Denkin said he will open the doors as soon as possible after that.

‘THERE’S NO CHEATING’

With millions of dollars at stake, growers and sellers have a clear incentive to get their marijuana approved.

At one meeting with growers, Denkin recalled, the topic of pricing for lab tests naturally came up.

Then someone asked: “How much is it to just pass everything?”

It was a joke, or perhaps not.

“Will there be bad guys in the industry? Maybe,” Denkin said. “There’s bad guys in every industry.”

High-tech tools will help prevent any possibility of tampering. Every bar code is linked to the grower’s batch number, and all the machines are tied to a real-time software system that makes results instantly available.

The clients — and the state — can log in and see them at a click.

“There’s no cheating,” Denkin said. “Numbers don’t lie.”

Asked how his lab will compete, he said with a smile, “I think that whoever opens first is going to get all the business.”

In the long run, though, Denkin thinks DigiPath’s selling point will be speed and consistency. It will promise a 48-hour turnaround on tests. The price for each test will range from $100 to $250, Denkin said, with a batch costing $500 to $1,000.

And DigiPath employees will work as if they are always being watched, with everything meticulously documented — in part because the state can audit them at any time.

“This will be run like a military operation,” Denkin said.

THE TESTS

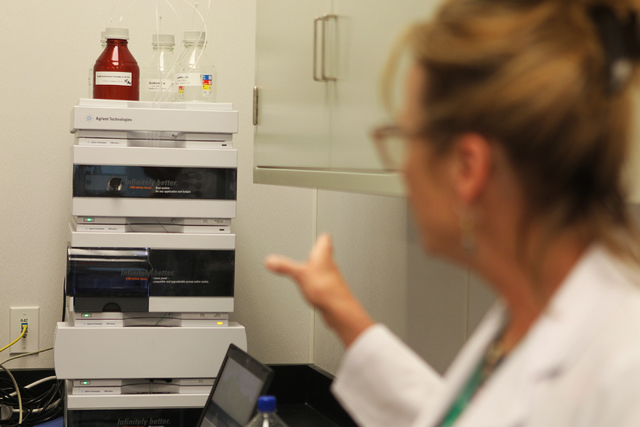

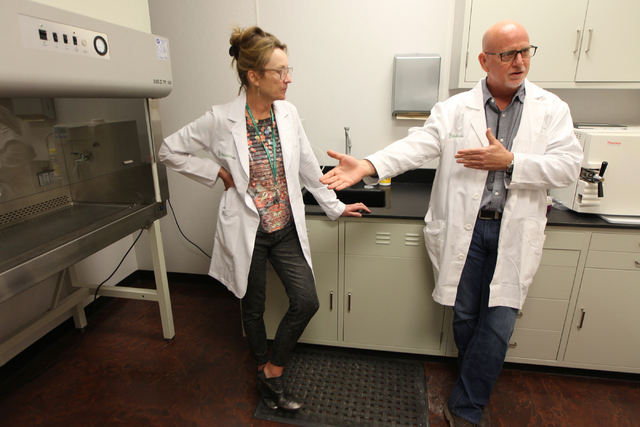

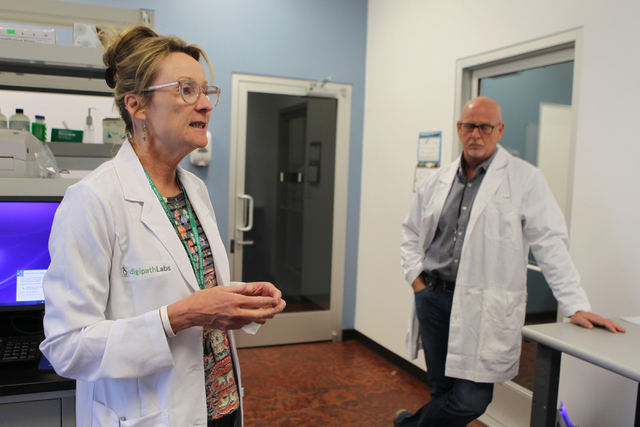

The company’s chief science officer, Cindy Orser, walked through the lab one day last week, showing how the testing will work.

Whenever a grower has a batch ready to be tested, a DigiPath employee will drive there, look at a 5-pound batch of “flower,” as the harvested marijuana plant is called, and randomly put 12 grams — one-half of 1 percent of it — into a sterile plastic bag.

Each 12-gram sample — an amount mandated by regulation — will get a unique bar code, as the state aims to track every batch “from seed to sale.”

Back at DigiPath, the marijuana will go first into an intake lab, where it will be weighed again and examined under a microscope. It will then be “homogenized” in a grinder, with dry ice as a preservative, so every gram is identical.

Lab assistants will load eight vials with 1 gram each. Staff will set aside 2 grams in a storage freezer in another room, in case any test later needs to be redone.

One sample will be weighed before and after it’s dried out, with the difference revealing the batch’s moisture content.

In a “micro testing lab” next door, another sample will be tested for E. coli and salmonella. There is zero tolerance for either, Orser said: Any positive test will mean the whole batch fails and can’t be sold.

It could still be turned into extract for use in edible products — which would then have to be retested — because the high-pressure extraction process kills the bacteria.

Other tests measure the levels of cannabinoids, the most well-known of which is THC; terpenoids, which give marijuana different odors and tastes; residual solvents; mycotoxins; and heavy metals: cadmium, mercury, lead and arsenic. In the micro lab, bacteria, yeast and fungi are measured.

The most sensitive — and most expensive — machine, the $250,000 one, will test for pesticide residue. It can be loaded with 100 vials from 100 different batches at once.

If a batch passes all the tests, the grower can log in online and print labeling information, which must be attached to every bit of marijuana sold in a dispensary.

The samples are largely destroyed in the testing process. Any leftover material will be destroyed via heat or chemically neutralized.

‘SAFE MEDICINE’

DigiPath, which was founded in 2010, first specialized in high-resolution images of tissue samples, which let doctors diagnose diseases remotely.

Last year, it received funding to get into the marijuana industry. Denkin, a longtime entrepreneur, previously developed hydroponic growing equipment used for marijuana and lettuce.

The company has been paying rent on its lab for a year, having signed a six-year lease.

It now has seven employees, but is hiring more and could add a second shift as the industry ramps up. An unfinished area next door to the lab gives DigiPath room to grow as the industry grows.

One calculation: The possible legalization of recreational marijuana in Nevada could mean exponential growth in the market for testing.

Several employees are chemists, and Orser has a doctorate from the University of California, Berkeley, in genetics and plant pathology.

Testing every batch of marijuana will be expensive, and the debate surrounding the rules has delayed the opening of dispensaries, frustrating patients and businesses.

But both state officials and people in the industry are confident that in the end, legal marijuana will be far safer in Nevada than elsewhere. In other states, testing is either inconsistent or nonexistent.

The Independent Laboratory Advisory Committee passed its recommendations Thursday, though the Division of Public and Behavioral Health still must issue formal guidelines.

Eventually, the state will come up with “proficiency testing” guidelines for labs, ensuring they are doing accurate work, but those guidelines aren’t ready yet.

Still, the state believes its inspections and audits will ensure lab testing is working well, said Chad Westom, who oversees the state’s medical marijuana program.

“This entire program is about providing safe medicine for patients,” Westom said.

Contact Eric Hartley at ehartley@reviewjournal.com or 702-550-9229. Find him on Twitter: @ethartley